Steel and Metal Production

High temperatures, strong acids, lots of noise, high impact, dust and steam... when working in steel or non-ferrous metal production, some of these conditions are probably part of your daily life. The machines used to transform ore into metal, and to form the metal, have to operate under the same conditions. And still: they need to be available all of the time, and customers require minimal product quality. This is a challenge, but not impossible.

Unexpected stops are costly and very demanding for the people involved: they demand a fast and solid solution. Often product quality only becomes an issue when customers start complaining. Stress is the result: the maintenance team because they go in "urgency" mode, and the production team because they are missing their targets. Our Virtual Engineers help you to make the critical assets in the plant smart, in order to avoid unplanned stops and obtain maximal efficiency when in use.

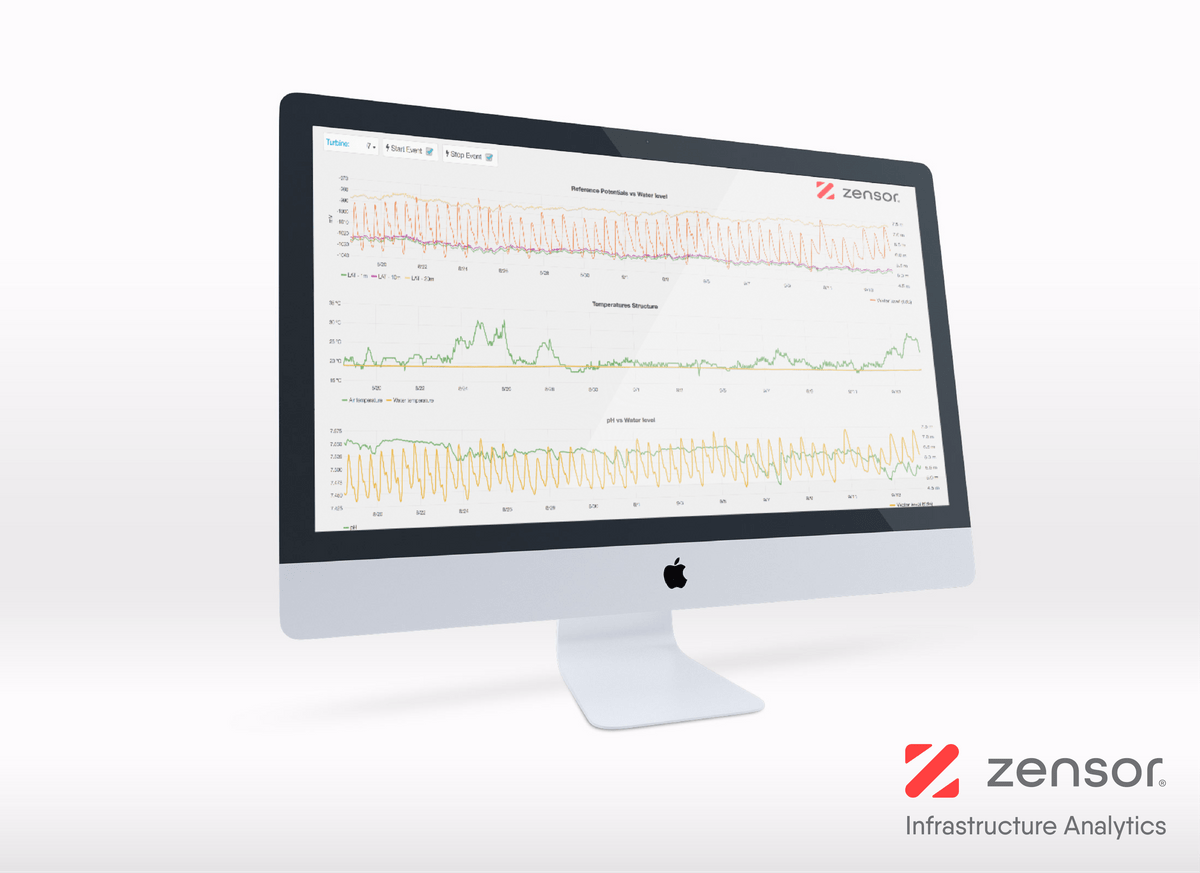

The only way to truly validate the actual health of crucial assets, predict upcoming issues, and check if the process is still according to specs is by deploying a specific multi-aspect monitoring setup on the machine or installation. This consists of different sensor types placed on specific locatons and a network of smart algorithms that is continuously transforming and interpreting the data. Zensor offer these solutions, so-called "Virutal Engineers" to provide and automated smart follow-up of the behaviour of critical machiens, tracking the general and component-specific state-of-health of the asset based on the streams.

Zensor has ready-made monitoring products for specific assets: Overhead Cranes (EOT Cranes, Gantry cranes, ladle cranes, scrap yard cranes...), Electric Arc Furnaces (EAF), Hot Rolling Mills, Conveyors, AOD Converters, BOF, Continuous Caster turrets as well as Continuous Casting lines (including segments), Cold Rolling lines, including shears, tensioners and welding stations, Cooling water pumps and de-scalers, ...

The result: less unforeseen stops, lower energy losses and a better control on product quality. What is there not to like?

“The insights generated give us peace of mind regarding the overall status of the overhead crane. Prioritising, quantifying and investigating maintenance tasks became easier, which in the long run, will result in the avoidance of unexpected shutdowns."

Some of our clients

"Predictive Maintenance is a buzzword. Zensor on the other hand offers real solutions to solve real problems, including context and helping you to prevent them from happening ever again."

We understand the problems you face

Catch them before they cause greater damage!

Standstills

Missing production targets due to equipment failure has a serious impact on your business and causes economic loss, delayed deliveries and demotivation among employees.Product quality

Not just the quality of the output but quality of the machinery - if your machine is deforming it will influence the quality of your output, causing greater bad yield.Yield optimisation

The faster the asset produces perfect output one after another, the less material has to be thrown away. A smart sensor set helps in setting the optimal set point to begin with and to rapidly reach the perfect conditions for each day.Availability

Increase the availability of your asset by only performing repairs when necessary, but also by changing the way you use the installation: true prevention.

Unknown root-cause

The right data is used to discover where the problem came from an which circumstances lead to the failure or stop.

Operational statistics

When continuously tracking currents or vibrations smart algorithms can determine automatically how long the asset operates under a certain condition. Live statistics give you insights into how optimally the asset is used.A typical steel plant process

Below a flow chart of a typical (integrated) steel plant or steel mill is depicted. It contains both process streams, bith the scrap-based as well as the ore-based route. In the future this flow chart will undergo massive changes, as for example DRI-based routed will replace the Blast Furnace process and Electric Arc Furnaces and also Induction ovens will take up the majority of the heavy lifting: the actual melting. Using the button below the chart a .pdf version of this chart can be downloaded.

Solutions for operational improvement:

Learn more about our approach

Performance

Based on the data collected and machine-learning based methods for determining the operational condition the performance is calculated.

Quality

Coupling to existing databases or using human input fields the product quality is linked to operational process parameters.

Warnings

Whenever values start to deviate, or data streams stop, warnings are sent. This avoids 'black holes' in the insights of the production line or assets.

Increase availability

Have a continuous idea of availability, automatically as the platform combines different input streams and contextual information.

Operational statistics

Often these statistics are available but not visible or known to the relevant stakeholders.

Health status

Having a real-time overview of your gantry cranes health status is vital to improving its overall efficiency on site.

Alerting

Reacting to particular events on your gantry crane is a lot more efficient and effective if you know what has, or is about to happenOur Experiences

Use case:

Use case:Aurubis Beerse

Belgium

We're helping Aurubis Beerse monitor the structural integrity of their critical overhead cranes. Read more in the case study.

Blog post:

Blog post:Save on operating costs while becoming smarter

In the production industry, machines and installations are one of the cornerstones of a company. How well they work and how high their availability is...

Blog post:

Blog post:How to be smart with data?

For a ‘smart’ follow-up of machines it is important not to rely on 1 source of truth. In reality this means that, in order to properly assess and predict the efficiency of operations and state-of-health of a machine, combinations are essential...

One pager:

One pager:Critical asset

Gantry Crane

Remote & continuous, multi-parameter health follow-up of your gantry crane.

We understand your problems and we're here to help.

Blog post:

Blog post:To eat a nice sandwich in the afternoon…

Everything can be solved with Data. At least that’s what we’ve read for years in glossy advertisements and seen in beautifully edited online videos. With sensors and IoT you can monitor all your machines...

Blog post:

Blog post:A new tomorrow for the manufacturing industry

As the post-covid-19 world is finally looming in some European countries, both individuals and organizations alike wonder what is to be learned from this unusual situation....

Download:

Success Case

A recent success case where our continuous monitoring of an EAF resulted in considerable cost savings

Blog post:

Blog post:Industry 4.0 in the world

For starters: we’re not a fan at all of the term, as it is the source for a lot of confusion and misunderstanding. However, as it is often used, we can’t just ignore it either. As such, for you the message that the fourth industrial revolution is about to...

Blog post:

Blog post:Experience at Hüttentag

Last week Zensor attended the Hüttentag in Essen. During this annual event the entire German steel industry meets up to discuss the state of affairs and exchange ideas about upcoming developments and changes...

Blog post:

Blog post:What does the future of maintenance look like?

With the economy going through a bit of a rough patch and revenue growth slowing down in different industries, companies are facing pressure to do something about their cost structure...

Blog post:

Blog post:Making Conveyors Smart

Conveyors form a cornerstone of many production plants and processes. The first conveyors have appeared near the end of the 18th century and since then their usage has only increased...

Blog post:

Blog post:A way out for long lead times for spare parts?

Lead times are a hot topic these days. It’s not at all uncommon to have to wait 4 or more months for components or spare parts that until recently could be delivered within a single week...

Blog post:

Blog post:Plant Managers aren't craving for AI

The main job of the Plant Manager is to keep the site running smoothly, whilst producing as many goods as efficiently as possible and using the resources provided..

Zensor NV

BE0537837878

© 2025