Offshore Wind

Offshore foundations for wind turbines (WTG) and/or substations (OSS) are designed to support the structure for the desired operational life of at least 20 to 25 years.

In the design stage all measures are taken to ensure the structure will reach its lifetime, but in practice the real state of health of the structures still comes with a degree of uncertainty. New concepts, assumptions regarding soil conditions and loads as well as unforeseen events all have an influence on how the structure or some of its key components degrade. This in turn influences the real state of health of the foundations.

The only way of having a continuous view on the foundation's state of health together with its evolution in time is by equipping it with a smart, multi-sensor monitoring solution.

We understand the problems you face

Catch them before they cause greater damage!

Design validation

In offshore wind often new or optimised designs are deployed. The most relevant source of learnings for any new farm are data generated in already operational farms. Equipping a set of turbines in your existing farm with a suitable monitoring setup will provide valuable insights to reduce development costs in your future farms

Structural fatigue

Everyone wants a tower that lasts longer and has lower costs to maintain. Knowing how the environmental factors are influencing the fatigue life of your tower/structure is critical increasing its operational life.

High maintenance costs

Lack of monitoring is guaranteed to increase your maintenance costs. How are you supposed to know when your tower/structure requires maintenance without knowing what is going on?

Displacements and deformations

The environmental factors can be extreme to an exposed structure. Monitoring the displacements and stresses from these factors can help you to increase its life cycle.

Downtime

Downtime is costly, especially for an expensive asset out in the ocean or in a remote windy location.

Flange monitoring with Smart Washers

Smart Washers can help to monitor the tightness of the bolts around the flanges of the towers.

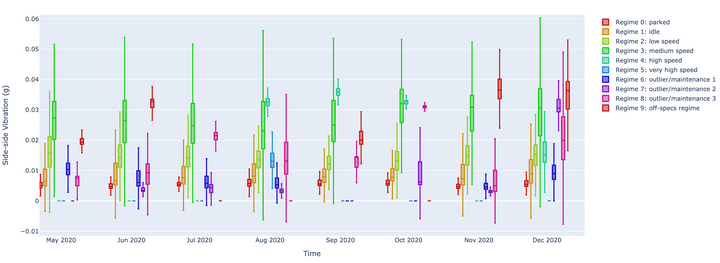

Operational regimes

See the distribution of regimes your turbine spends over time

Weather module

Combine the sensor data with weather to understand the influences of the environment on your turbine and its operationsOur Experiences

Projects we're working on:

Projects we're working on:Van Oord - Borssele V Wind Farm

The Netherlands

Zensor is monitoring corrosion parameters on the innovative Slip Joint installed in the Borssele V wind farm.Download:Wind Turbine Doctor

Predictive maintenance is no longer something that is reserved for big multinationals active in very specific industries.... Projects we're working on:

Projects we're working on:Blauwwind - Borssele III & IV Wind Farm

The Netherlands

Zensor is monitoring the fatigue life of 5 different towers in the Borssele III and IV wind farm. Projects we're working on:

Projects we're working on:Eneco Luchterduinen Wind Farm

The Netherlands

Zensor is monitoring the fatigue life of 4 different towers in the Luchterduinen Wind Farm. This project has been running since 2016.Looking for applications in other sectors?

Zensor NV

BE0537837878

© 2025