Conveyors

Unexpected shutdowns are costly and very demanding for the workforce involved. Make your conveyors smart in order to increase their availability.

Today most often technical data sheets coupled with the knowledge of a number of unique experienced individuals are used to determine when maintenance is required for the conveyor. Product quality only becomes an issue when customers start complaining. Repairs are done when it's already far too late. All of this puts tremendous strain on the people responsible for conveyor belt, while it can be avoided, quite easily.

The only way to validate the actual health is by having a continuous look at a broad data set and adding a specific multi-aspect monitoring setup consisting of different sensor types that follow the behaviour of the conveyor's general state-of-health.

We understand the problems you face

Catch them before they cause greater damage!

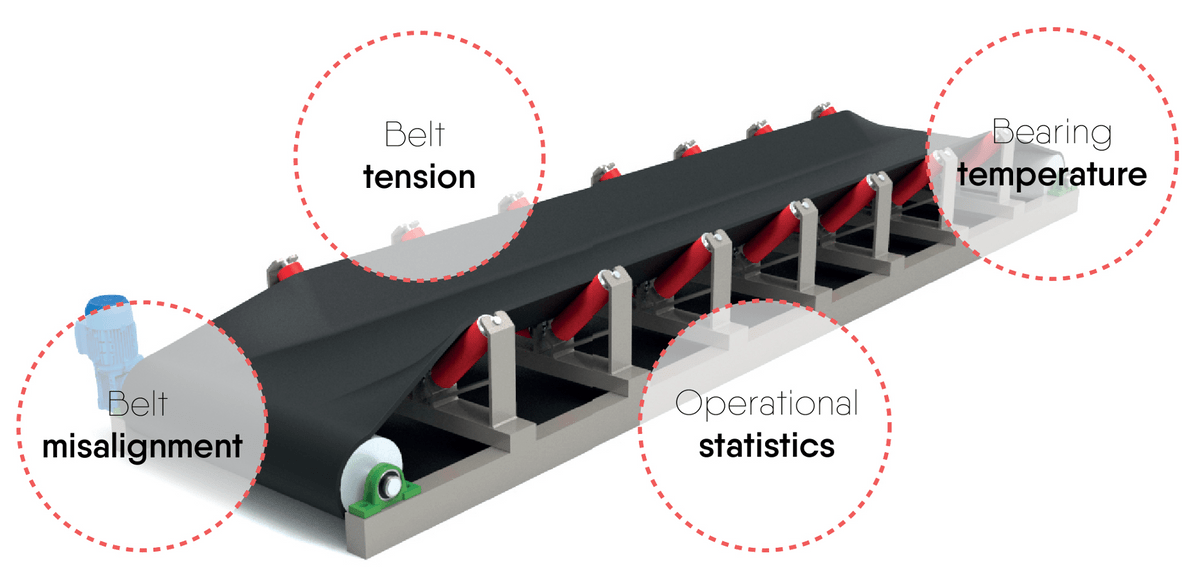

Belt Tension

A well-controlled tension is essential for smooth operations. Constant tension monitoring will avoid excessive wear, slip or rupture.Belt Alignment

A belt not running straight is a belt prone to damage or a prelude to a blocked system. Continuous tracking of the alignment allows maximally preventing unexpected standstills.Motor Health

Motors suffer from ageing, but also from excessive loading or friction within the system. Correlating motor currents with vibrations and operational parameters helps in reducing motor degradation and detecting damage in an early stageBearing Temperature Control

In dusty environment high temperatures represent danger. Classical controls stop an installation when a threshold is exceeded. A smart system provides a warning when heating starts, such that sudden stops can be avoided.Belt Wear Monitoring

Wear is caused by friction and causes premature ageing. Monitoring through temperature mapping or vibration levels helps in prolonging operational life through minimising wear.Operational Statistics

When continuously tracking currents or vibrations smart algorithms can determine automatically how long the belt operates under a certain condition. Live statistics give you insights into how optimally the asset is usedGEARBOX HEALTH | BELT SLIPPING | BEARING ALIGNMENT | MATERIAL BUILDUP | CHAIN CONVEYOR | CHAIN WEAR | BELT CONVEYOR

Compatibility

All of Zensor's products are compatible with standard CMMS or EAM software. Connections can be set up to source the most recent interventions and changes on the asset, or to create a ticket when an intervention is required on a conveyor. Compatible with:

- IBM Maximo

- IFS Ultimo

- eMaint CMMS

- Aveva

- SAP

- ...

Solutions

Learn more about our approach

Performance

Based on the data collected and machine-learning based methods for determining the operational condition the performance is calculated.Quality

Coupling to existing databases or using human input fields the product quality is linked to operational process parameters.Warnings

Whenever values start to deviate, or data streams stop, warnings are sent. This avoids 'black holes' in the insights of the production line or assets.Increase availability

Have a continuous idea of availability, automatically as the platform combines different input streams and contextual information.Our Experiences

Projects we worked on:

Projects we worked on:Meyland - Agriculture

Belgium

Zensor have been working with Meyland to monitor their new innovative conveyor belt design so they can bulk manufacture and send them all over the world.

Blog post:

Blog post:Save on operating costs while becoming smarter

In the production industry, machines and installations are one of the cornerstones of a company. How well they work and how high their availability is...

Blog post:

Blog post:How to be smart with data?

For a ‘smart’ follow-up of machines it is important not to rely on 1 source of truth. In reality this means that, in order to properly assess and predict the efficiency of operations and state-of-health of a machine, combinations are essential.

One-pager:

One-pager:Specific one pager

Find out how we can help solve your greatest challenges when working with and monitoring a conveyor belt.

Blog post:

Blog post:To eat nice sandwich in the afternoon...

Everything can be solved with Data. At least that’s what we’ve read for years in glossy advertisements and seen in beautifully edited online videos. With sensors and IoT you can monitor all your machines...

Blog post:

Blog post:Zensor Experience at Bauma 2022

The last week of October 2022 the most recent edition of Bauma took place. For Zensor this was an event with a double goal. The main one was the official launch of the SmartSheetPile together with ArcelorMittal, a second one was related to discovering new developments in a number of industries we’re active in...

Blog post:

Blog post:Industry 4.0 in the world

For starters: we’re not a fan at all of the term, as it is the source for a lot of confusion and misunderstanding. However, as it is often used, we can’t just ignore it either. As such, for you the message that the fourth industrial revolution is about to...

Blog post:

Blog post:Experience at Hüttentag

Last week Zensor attended the Hüttentag in Essen. During this annual event the entire German steel industry meets up to discuss the state of affairs and exchange ideas about upcoming developments and changes...

Blog post:

Blog post:Making Conveyors Smart

Conveyors form a cornerstone of many production plants and processes. The first conveyors have appeared near the end of the 18th century and since then their usage has only increased...

Blog post:

Blog post:A way out for long lead times for spare parts?

Lead times are a hot topic these days. It’s not at all uncommon to have to wait 4 or more months for components or spare parts that until recently could be delivered within a single week...

Looking for another asset?

Zensor NV

BE0537837878

© 2025