Food Processing

Unexpected shutdowns are costly and very demanding for the workforce involved. Make your production critical food processing asset smart in order to increase the availability.

Today most often technical data sheets coupled with the knowledge of a number of unique experienced individuals are used to determine when maintenance is required for an asset. Product quality only becomes an issue when customers start complaining. Repairs are done when it's already far too late. All of this puts tremendous strain on the people responsible for the production line, while it can be avoided, quite easily.

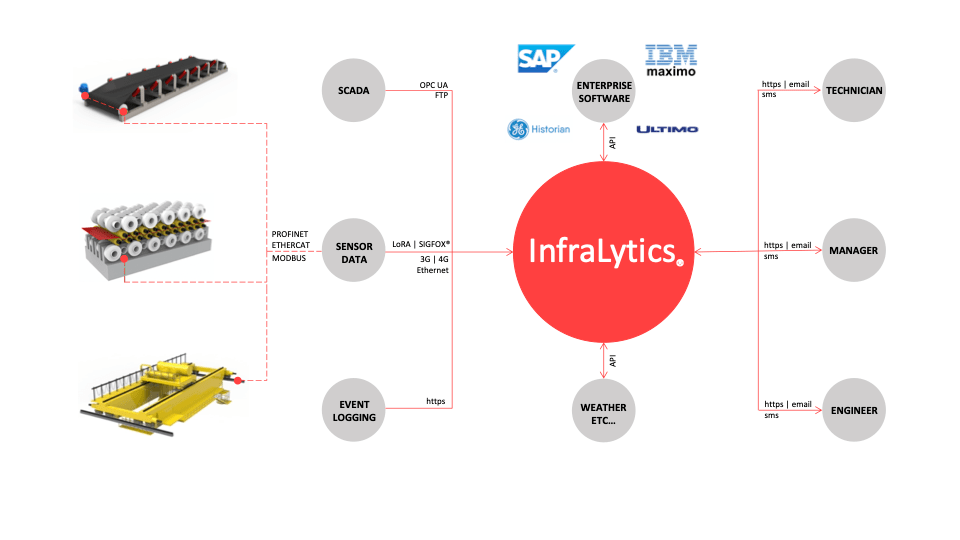

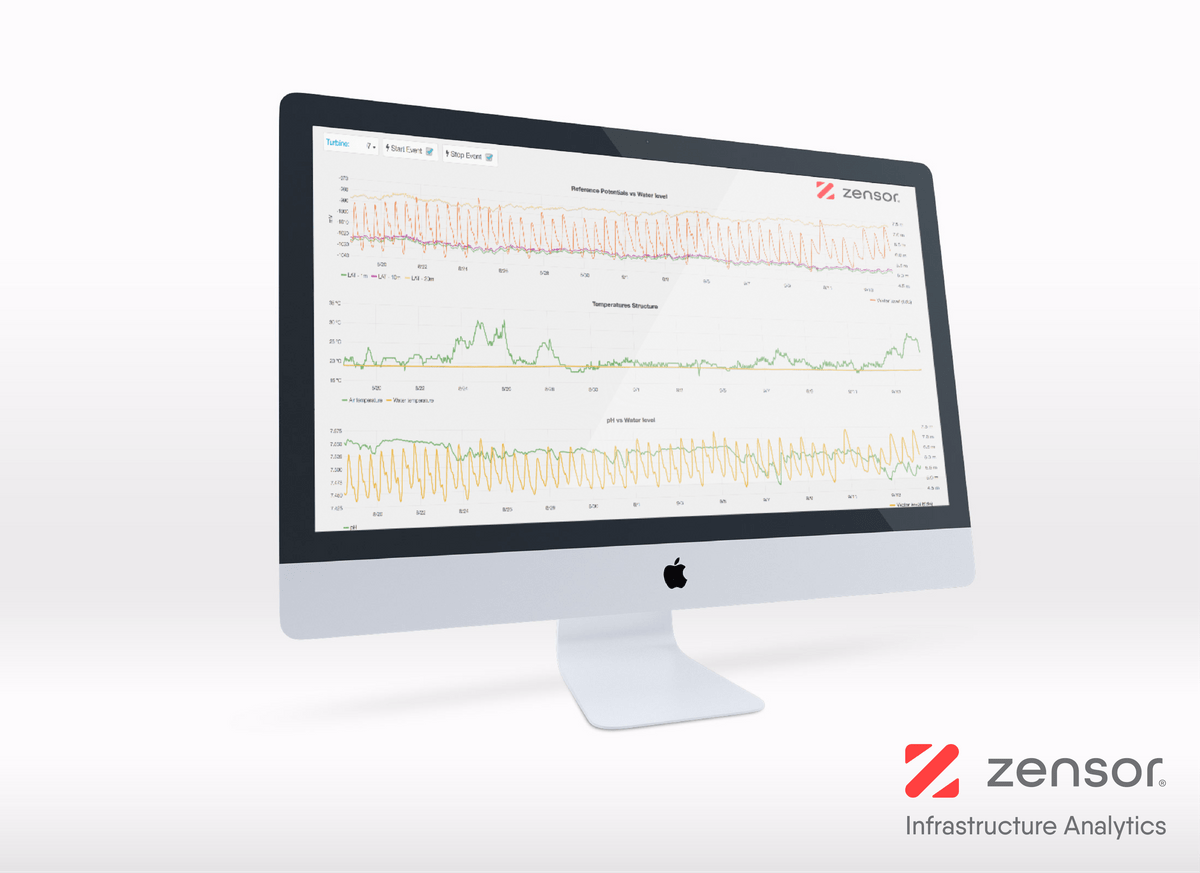

The only way to validate the actual health of crucial assets is by having a continuous look at a broad data set and adding a specific multi-aspect monitoring setup consisting of different sensor types that follow the behaviour of critical components and the general state-of-health of the asset.

Zensor has ready-made solutions for Ovens, Conveyors, Mixers, Extruders...

Looking for a specific asset?

We understand the problems you face

Catch them before they cause greater damage!

Standstills

Missing production targets due to equipment failure has a serious impact on your business and causes economic loss, delayed deliveries and demotivation among employees.Product quality

Not just the quality of the output but quality of the machinery - if your machine is deforming it will influence the quality of your output, causing greater bad yield.Yield optimisation

The faster the asset produces perfect output one after another, the less material has to be thrown away. A smart sensor set helps in setting the optimal set point to begin with and to rapidly reach the perfect conditions for each day.Availability

Increase the availability of your asset by only performing repairs when necessary.Unknown root-cause

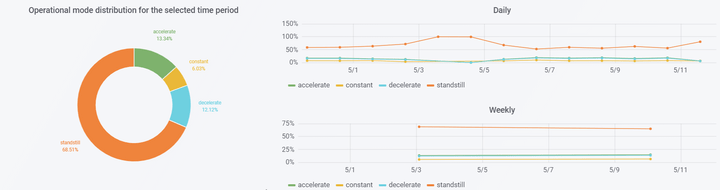

Use the right data to discover where and how the problem came from.Operational statistics

When continuously tracking currents or vibrations smart algorithms can determine automatically how long the asset operates under a certain condition. Live statistics give you insights into how optimally the asset is used.Solutions

Learn more about our approach

Performance

Based on the data collected and machine-learning based methods for determining the operational condition the performance is calculated.Quality

Coupling to existing databases or using human input fields the product quality is linked to operational process parameters.Warnings

Whenever values start to deviate, or data streams stop, warnings are sent. This avoids 'black holes' in the insights of the production line or assets.Increase availability

Have a continuous idea of availability, automatically as the platform combines different input streams and contextual information.

Event and status log

Be alert and learn about the evolution of unusual events that are damaging to your asset.

Operational status

Simple but effective! The benefit of knowing how exactly your asset is spending the majority of its time is hugely value, without having to be on site.Our Experiences

Brochure:

Brochure:Plant Owner

The opportunities towards smart maintenance, more efficient production or faster decision making through digitalisation are infinite. But these targets can be daunting to start with. So start NOW!

Blog post:

Blog post:Save on operating costs while becoming smarter

In the production industry, machines and installations are one of the cornerstones of a company. How well they work and how high their availability is....

Blog post:

Blog post:How to be smart with data?

For a ‘smart’ follow-up of machines it is important not to rely on 1 source of truth. In reality this means that, in order to properly assess and predict the efficiency of operations and state-of-health of a machine, combinations are essential...

Blog post:

Blog post:To eat a nice sandwich in the afternoon…

Everything can be solved with Data. At least that’s what we’ve read for years in glossy advertisements and seen in beautifully edited online videos. With sensors and IoT you can monitor all your machines...

Blog post:

Blog post:A new tomorrow for the manufacturing industry

As the post-covid-19 world is finally looming in some European countries, both individuals and organizations alike wonder what is to be learned from this unusual situation...

One pager:

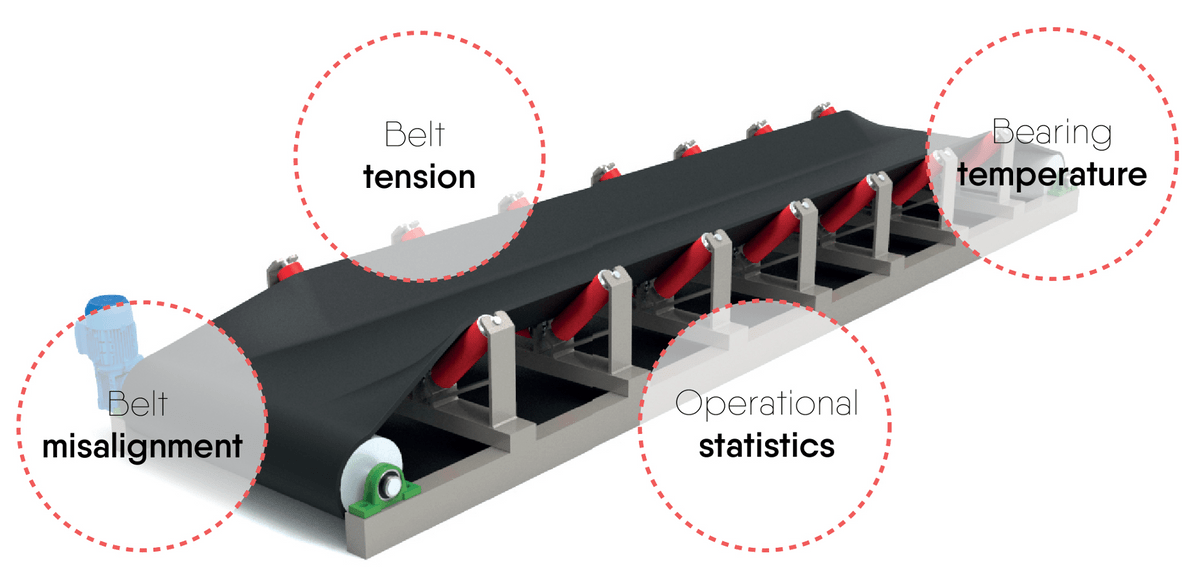

One pager:Conveyor Belt

Remote & continuous, multi-parameter health follow up of your critical production asset - the conveyor belt

Blog post:

Blog post:Industry 4.0 in the world...

For starters: we’re not a fan at all of the term, as it is the source for a lot of confusion and misunderstanding. However, as it is often used, we can’t just ignore it either. As such, for you the message that the fourth industrial revolution is about to...

Blog post:

Blog post:What does the future of maintenance look like?

With the economy going through a bit of a rough patch and revenue growth slowing down in different industries, companies are facing pressure to do something about their cost structure...

Blog post:

Blog post:Making Conveyors Smart

Conveyors form a cornerstone of many production plants and processes. The first conveyors have appeared near the end of the 18th century and since then their usage has only increased...

Blog post:

Blog post:A way out for long lead times for spare parts?

Lead times are a hot topic these days. It’s not at all uncommon to have to wait 4 or more months for components or spare parts that until recently could be delivered within a single week...

Blog post:

Blog post:Plant Managers aren´t craving for AI

The main job of the Plant Manager is to keep the site running smoothly, whilst producing as many goods as efficiently as possible and using the resources provided...

Zensor NV

BE0537837878

© 2025