Rail

Completely integrated monitoring solutions render your high-quality structural elements into an intelligent rail network. To achieve this, the rail elements are equipped with the required sensing components. In our scope are bridges (steel and concrete), tunnels, overhead line equipment, embankments, switches...

The associated continuous monitoring systems are activated once the element has been put into operation. It continuously provides live insights on the structural health of the element, creating a transparent view on its condition and structural integrity.

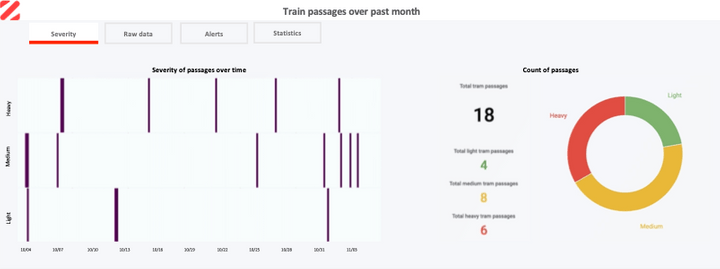

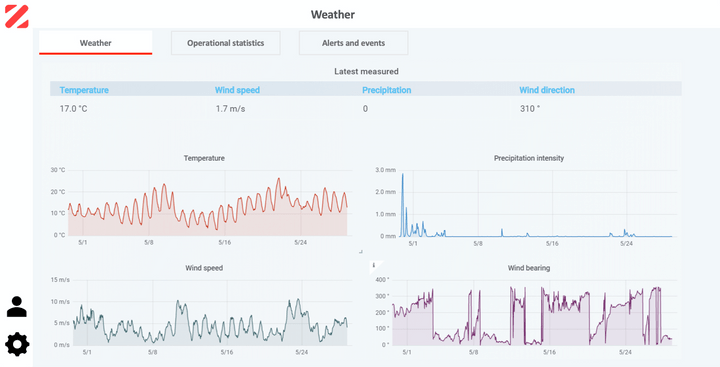

Furthermore, integrated sensors and the associated follow-up algorithms predict when things will go wrong, identify deviations in behaviour and provide new insights on the impact of relevant parameters of the environment the structure is operating in, such as temperature, humidity, displacements, vibrations,... Also operational loads (passages) are tracked and taken into account to generate a full picture of the behaviour.

We understand the problems you face

Catch them before they cause greater damage!

High maintenance costs

An inadequately close follow-up is guaranteed to result in very high maintenance costs (as maintenance classically is done when it's already too late, and is accompanied by corrective or repair actions). How are you supposed to know when your asset requires maintenance without knowing what is going on?Displacements and deformations

The influence of environmental factors on an exposed structure can be extreme. Monitoring the resulting displacements and stresses can help you to increase its life cycle and to discriminate between issues that require attention and natural (background) evolutions..Unknown root-cause

Use the right data to identify deviations an early stage, or at least to determine where and how the problem came from.Availability

Increase the availability of your asset by preventing large-scale damage and through performing repairs in-time and when necessary.

Detect and classify train passages

Know what trains or passages are most damaging to your rail and surrounding infrastructure

Weather module

Utilise surrounding weather API's to know what is happening around your assetOur Experiences

Projects we're working on:

Projects we're working on:TUC Rail

Mechelen, Belgium

Zensor is monitoring the structural integrity of the Mechelen steel train bridge. We're helping TUC Rail and Infrabel understand the damaging properties to extend the life span of the bridge. Projects we're working on:

Projects we're working on:BAM

Antwerp, Belgium

Zensor is monitoring the structural integrity and influence that passing trams have on the switch which determines the direction of the trams in Antwerp.

Zensor NV

BE0537837878

© 2025